vectis cobot

The Vectis Cobot Welding Tool is one way the nexAir team uses KnowHow to make your projects easier and more efficient.

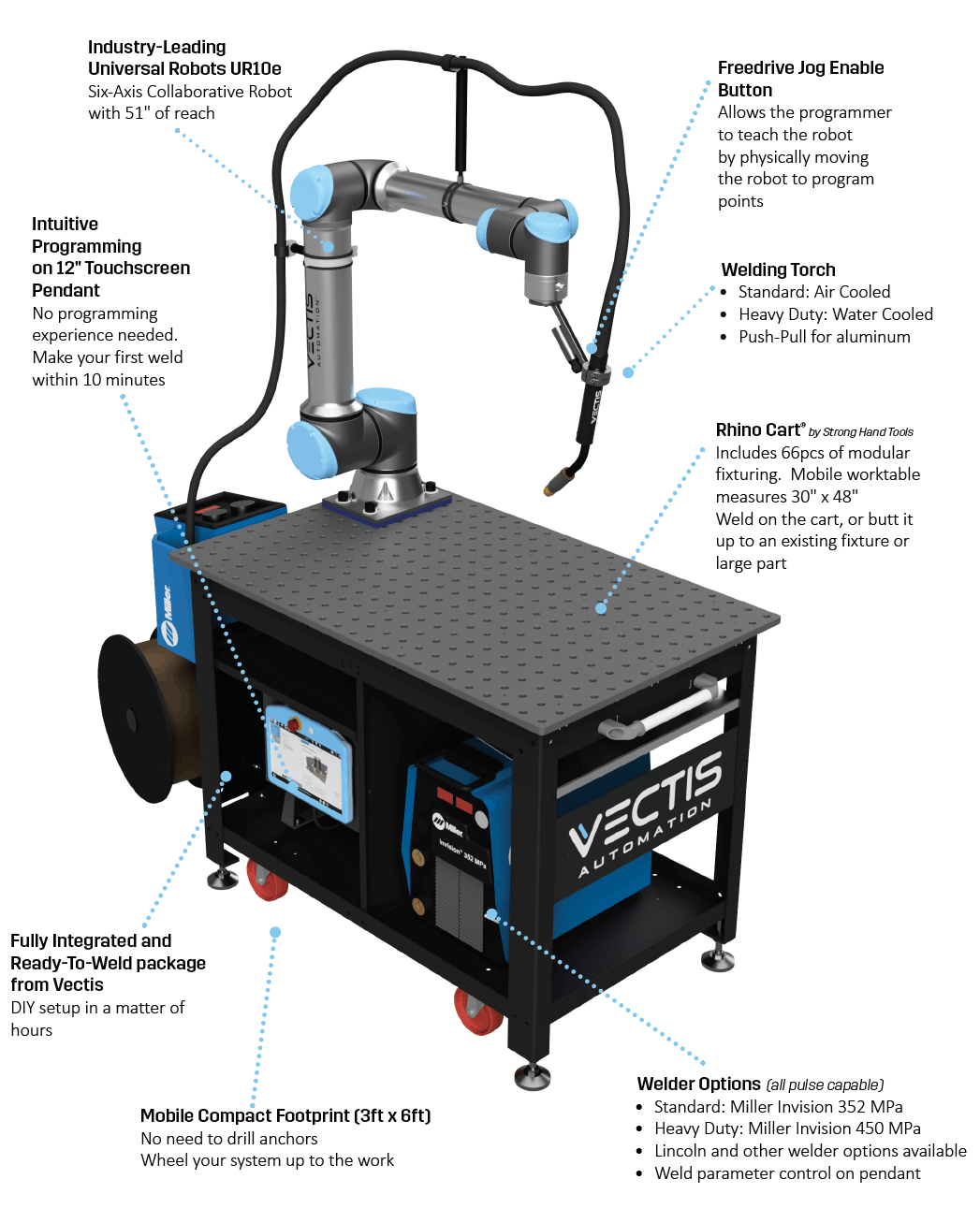

Features and Benefits:

Peace-of-Mind:

- Safety Net 30-Day Return Program: Return within 30 days for a full refund, no questions asked.

- Try Before You Buy rental and rent-to-own programs.

- Honest and upfront Application Evaluations at no cost to you.

- Lifetime Technical Support. Quick response times enabled by remote video chat (FaceTime, GoToMeeting, etc).

Lower Cost:

- Our Cobot Welding Tool is often 25-40% less than the all-in cost of a traditional robot cell.

- DIY installation, setup, and training – no need to fly to our facility nor pay a tech to come on-site.

- Shipping is included in our price. Most traditional systems require a costly dedicated air-ride semi.

Extreme Ease-Of-Use plus handy Software Features for welding:

- No programming experience needed: Make your first weld within 10 minutes after plug-in.

- Weld Template Library provides you with parameter starting points for common weld sizes.

- Handy software features include Seam Tracking, Pattern, Stitch, Tack, Touch Sensing, MultiPass.

- More features are continually being developed by Vectis’ in-house Welding Software Team.

Witness the ease and efficiency of the Vectis Cobot Welding Tool.

Get into production faster:

- Our solution ships to you in a few short weeks.

- Most customers are setup and in production within hours or days of system arrival.

- DIY commissioning – no need to fly to weeklong training classes nor pay to have our tech on-site.

Collaborative Robot (Cobot) Technology:

- Freedrive Jog allows the programmer to teach by physically moving the cobot to program locations.

- Built-in safety allows the cobot to safely work alongside humans, without permanent barriers.

- During production gaps in the weld shop, the cobot arm can even be repurposed to other tasks.

Portable, Compact, and Versatile:

- Mobile and compact footprint – only 3ft x 6ft

- Bring the Cobot Welding Tool to the work – no need for a dedicated footprint or work envelope.

- Use the Rhino Cart surface to weld smaller parts; or wheel it up to a stationary part or existing fixture.

- Versatile utility setup: system can interchangeably run on single-phase or three-phase power.

Download the free whitepaper

What Is The Vectis Cob0t

CNC Plasma Cutting Systems

LightWELD

Welding Positioners

Connect With Us

Use this form to get in touch with our team of welding automation experts. Let’s find out if the Vectis Cobot system from nexAir is right for your company.