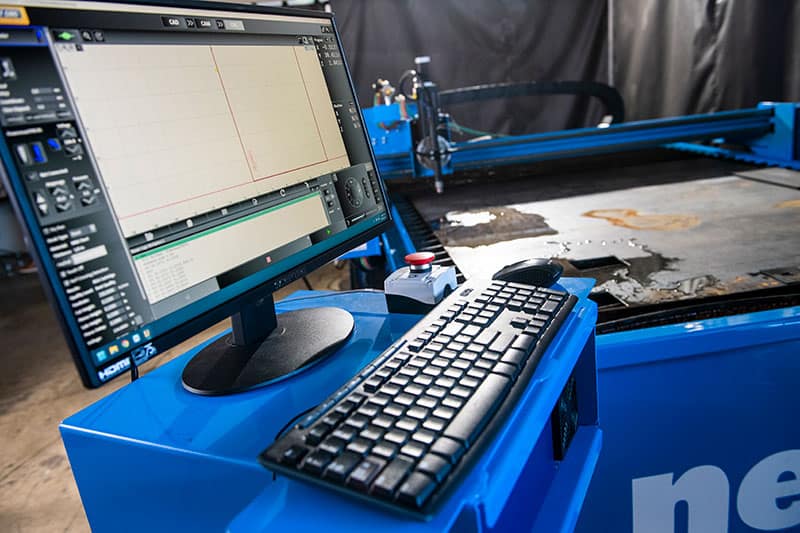

CNC PLASMA CUTTING SYSTEM

Affordable, high speed, and easily deployable.

nexAir Cutting CNC plasma systems are the perfect machines for anyone looking for high-quality cutting, affordability and ease-of-use.

Look no further for an industry-leading CNC cutting solution.

See for yourself.

Maximum Impact in a Minimal Package.

HIGH PERFORMANCE.

SMALL FOOTPRINT.

Make the most of your floor space and boost your bottom line forever.

LESS DOWNTIME. MORE CUTTING.

Reliable, fast and low-maintenance. More cutting means more productivity.

Run on Day One—

And Keep Running

No assembly. No hassle. No wasted time ramping up to production.

Easy to Use. Simple to Maintain.

Enjoy minimal training time and set your team in motion in no time flat.

Key Features

BASE FRAME

- Heavy-duty construction yields reliable movement and precise cuts

- Fully welded main support frame

- Powder-coated exterior covers

- Power track on X and Y-axis

- Adjustable leveling feet

BRIDGE

- Rigid anodized aluminum extrusion beam

- Machined end truck and linear guide surfaces

- Dual side drive

- 20mm linear guides on all axes

- Outward-facing gear rack for splatter protection

- Ball screw lifter

CONTROL & SOFTWARE

- Micro stepping control box with CNC software

- Draw, Nest, Cut with complete CAD/CAM/CNC software

- Torch height control

- Surge protector

Discuss the limitless possibilities with our team of experts.

nexAir Cutting Tables: Advantages

Waterjet cutters and similar solutions are time-consuming to use and slow to complete a project, which limits productivity and impacts the volume of work one can take on. As the market gets busier and demand increases, this cuts into potential work and caps profits from additional projects. Not to mention, legacy solutions are costly to maintain and almost impossible to keep online and operational as often as they are needed.

The nexAir CNC Plasma Cutting System takes projects from design to completion in record time, allowing users to complete more projects for more customers—and even expand their service offerings—which boosts bottom lines and raises profits.

With the CNC Plasma Cutting System, users free themselves of the struggles of complicated, expensive to maintain equipment that works at slow speeds. Many users even find that they no longer have to modify parts in the field; they can offer customers first-order parts rather than modified projects. Plasma cutter can even handle large raw stock, and it comes with low operating costs and simple upkeep.

What’s more, users can get started almost right away, with very little start-up or lead time needed for production. As soon as it’s installed, users can get to work immediately.